It’s 9:00 PM. A major terminal goes down; prices are spiking 20 cents at midnight, and two drivers just called in sick. In the traditional fuel world, this is where the firefighting begins. What follows is a frantic night of phone calls, manual re-dispatching, and margin erosion.

For years, the industry has tried to solve this issue. First, it was “digitization.” Then “automation.” Now, the buzzword is autonomy. The promise is compelling: A supply chain that senses a disruption, calculates the least-cost alternative, and re-routes the trucks before a human even pours their first cup of coffee. But beneath the headlines, retailers and wholesalers are asking a more grounded question: Is this actually possible, and how close are we, really?

The answer is less about futuristic AI and more about operational readiness. Autonomy isn’t a product you buy; it’s a capability you build.

Autonomy Is Not a Switch. It Is a Spectrum.

One of the most common mistakes is treating autonomy as a binary outcome. In reality, it is a spectrum of trust and delegation:

- Descriptive: The system tells you what happened.

- Predictive: The system tells you what might happen (an outage or price move).

- Prescriptive: The system recommends a specific action for a human to approve.

- Autonomous: The system executes the action within defined guardrails and alerts the human of the result.

True autonomy acknowledges that no plan survives contact with the midday price change. It’s not about building a perfect plan; it’s about continuous re-optimization.

From Friction to Flow

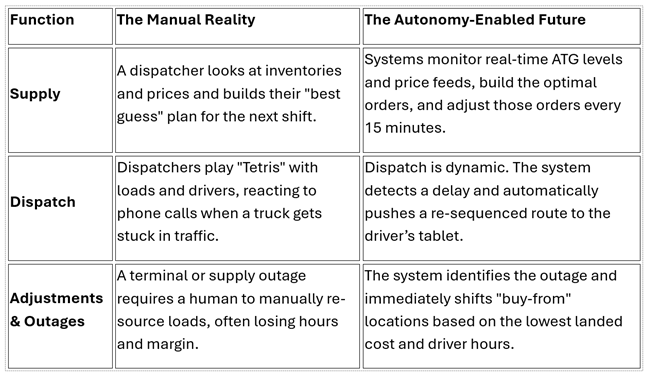

To understand how close we are, we have to look at how the daily workflow will actually change.

How Close Are We Really?

As Bill Gates once observed, people often overestimate what they can do in one year and underestimate what they can do in ten years.

That insight applies directly here. Full autonomy will not arrive next year, and organizations expecting an overnight transformation will be disappointed. But autonomous dispatch is coming faster than many think.

From a technical standpoint, the building blocks already exist. Optimization engines, forecasting models, carrier integrations, real-time data feeds, and automation frameworks are no longer experimental.

From an operational standpoint, most organizations are still in transition.

A realistic view is that meaningful autonomy is two to three years away for retailers and wholesalers who actively invest in readiness today. That does not mean waiting for perfection. It means starting with well-defined workflows and expanding from there.

The first gains come from intraday optimization, not end-to-end autonomy. Systems that can react to price moves, outages, and execution signals within minutes rather than hours create immediate value. Over time, those systems earn the trust required to take on more responsibility.

The Real Barriers (It’s Not the AI)

If the technology exists, why isn’t everyone autonomous yet?

- The Trust Gap in Data: Autonomous systems require “high-fidelity” data. If your forecast is off by 500 gallons or your price feeds lag by an hour, the AI will make a “perfectly logical” decision that is factually wrong.

- The Language Barrier: Today, fuel operations rely on tribal knowledge: knowing that “Product X” at “Terminal A” is interchangeable with “Product Y” at “Terminal B.” Autonomy requires this to be codified into standardized reference data.

- Healthy Skepticism: Fuel is dangerous, expensive, and unforgiving. “Black box” logic doesn’t work here. Operators need “Glass Box” autonomy, where they can see why a system made a certain decision, and override it instantly if common sense dictates otherwise.

What Leaders Are Doing Now

The organizations that will win the next decade aren’t waiting for a “finished” autonomous solution. They are engaging now by:

- Investing in Data: Choosing best-in-class vendors and solutions to help them collect the high-fidelity data they need to run their businesses.

- Cleaning the Foundation: Extracting and maintaining their reference data and transactional data for reporting and integrations. Ensuring data integrity and data quality standards.

- Moving to Intraday Cycles: Shifting away from static planning periods toward systems that can ingest data and pivot more dynamically. Looking for quick wins and low-hanging fruit when it comes to automation.

- Investing in AI Literacy: Learning how to prompt. Understanding what agents are capable of. Separating real capability from hype. This matters because AI is no longer a niche technology. It is embedded in daily workflows across industries. Fuel supply chains will not be an exception.

Across the industry, platforms such as Gravitate are beginning to connect supply, pricing, and dispatch into closed-loop systems that can sense, decide, and act in near real-time. The lesson is not about any one platform. It is about the direction the industry is moving.

Organizations that engage now will be able to decide what should be automated and what should not. Those who wait will be forced to react.

What about the Humans?

Perhaps the most misunderstood aspect of autonomy is its impact on people. Autonomy doesn’t replace the logistics professional; it promotes them. The human moves from crisis responder to exception manager.

When the system handles 90% of loads that go according to plan, the human is finally free to focus on 10% that requires genuine judgment, relationship-building, and high-stakes negotiation. The future fuel organization isn’t necessarily smaller; it’s just much, much faster.

The time to engage is now. Autonomy is not something to wait for; it is something to shape.